Polypropylene (PP) is a leading thermoplastic, known for its rigid yet adaptable nature, making it perfect for everyday items like packaging trays, battery cases, medical devices, and more. Part of the polyolefin family, it’s among the top three most-used polymers worldwide. PP’s ultra-low density means it’s incredibly lightweight without sacrificing strength.

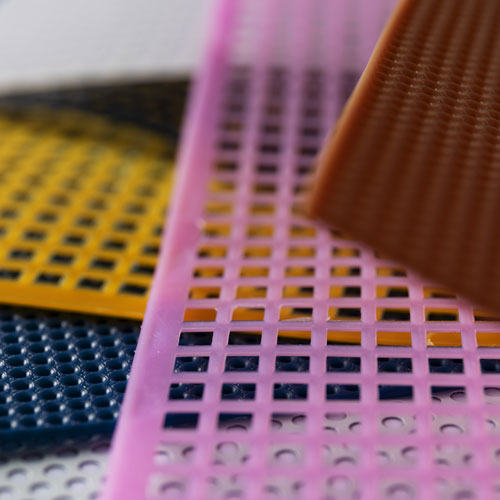

Polyethylene (PE) is a versatile, lightweight, and durable thermoplastic—widely produced for countless industries. At GB Plas, we offer both High-Density Polyethylene (HDPE) and Low-Density Polyethylene (LDPE). Each has distinct properties to meet your unique requirements, whether you need strength or flexibility. Here’s a quick guide:

Among commodity plastics, PP is lightweight yet tough, ideal for a range of applications.

Suitable for packaging, automotive parts, and textiles.

Resists chemicals and bending, making it perfect for hinges, lids, and high-use items.

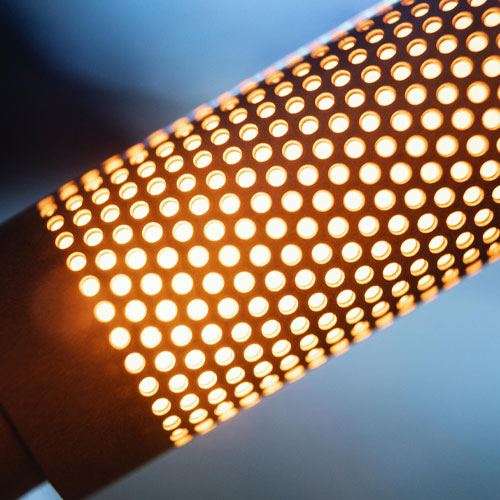

Ideal for electrical goods or products exposed to moisture.

Smooth surface, great for moving parts in machinery.

Strong, lightweight, and affordable.

HDPE is your go-to choice for applications requiring strength, rigidity, and heat resistance. It’s highly durable with a high tensile strength, making it perfect for heavy-duty products that need to withstand demanding conditions. HDPE is opaque, offering strong UV protection and superior resistance to acids, bases, oils, and solvents.

LDPE offers excellent flexibility even at low temperatures, making it ideal for products needing durability without compromising flexibility. LDPE's semi-transparency and impact resistance allow it to absorb shocks, making it great for protective films, bags, and flexible pipes. It’s a lightweight, affordable solution that doesn’t compromise on quality.

|

Properties

|

HDPE

|

LDPE

|

|---|---|---|

|

Density

|

Higher (0.941 to 0.965 g/cm³)

|

Lower (0.910 to 0.940 g/cm³)

|

|

Tensile Strength

|

Higher, suitable for strong applications

|

Lower, great for flexible uses

|

|

Rigidity

|

Rigid under stress.

|

Less rigid, more flexible.

|

|

Flexibility

|

Less flexible

|

Highly flexible event at low temperature

|

|

Impact resistance

|

Resistant to deformation

|

Excellent shock absorption

|

|

Lightweight

|

Moderate weight

|

Lightweight, easy to handle

|

|

Heat resistance

|

Higher, suitable for high-temp applications

|

Moderate heat resistance.

|

|

Transparency

|

Opaque, blocks UV light.

|

Semi-transparent with a cloudy appearance.

|

|

Chemical resistance

|

Resistant to acids, bases, oils, grease and various organic solvents.

|

Good resistance to acids and bases but softens with certain solvents and oils.

|

Lightweight and Rigid, Ideal for Various Applications

Essential for secure, lightweight packaging solutions.

Perfect for furniture, housewares, and toys.

Used in everything from interior parts to battery casings.

Sturdy and resilient in fabrics, ropes, and carpets.

Food containers able to be microwaved and dish washed.

Suitable for a wide range of high-demand applications.

|

Properties

|

Specification

|

|---|---|

|

Thickness

|

0.5mm to 12.0mm (+/- 0.2mm)

|

|

Maximum Width

|

1220mm (1.22m)

|

|

Length

|

No limit

|

|

Colour

|

Standard (refer colour catalogue) or custom colours.

|

|

Standard Sizes

|

1.22m x 1.83m

1.22m x 2.44m |

For Strong, Rigid Applications Needing Heat Resistance

Heavy-duty containers, bottles.

Furniture, housewares, toys

Sturdy and resilient in fabrics, ropes, and carpets.

Used as protective layers of PC Hollow.

|

Properties

|

Specification

|

|---|---|

|

Thickness

|

0.5mm to 12.0mm (+/- 0.2mm)

|

|

Maximum Width

|

1220mm (1.22m)

|

|

Length

|

No limit.

|

|

Colour

|

Standard (refer colour catalogue) or custom colours.

|

|

Standard Sizes

|

1.22m x 1.83m

1.22m x 2.44m |

Film wraps, bags, and plastic bags.

Flexible pipes and plumbing solutions.

Used as colour coating of GB Bond.

|

Properties

|

Specification

|

|---|---|

|

Thickness

|

0.5mm to 12.0mm (+/- 0.2mm)

|

|

Maximum Width

|

1220mm (1.22m)

|

|

Length

|

No limit.

|

|

Colour

|

Standard (refer colour catalogue) or custom colours.

|

|

Standard Sizes

|

1.22m x 1.83m

1.22m x 2.44m |

|

Colour

|

Standard (refer colour catalogue)

|

Our experts are here to help. Contact us today for a free quote and let GB Plas guide you to the perfect solution!

© 2024 GB Plas Sdn Bhd (638291-V) Powered by Zoewebs – Web Design Malaysia